How An African Bird Might Inspire A Better Water Bottle

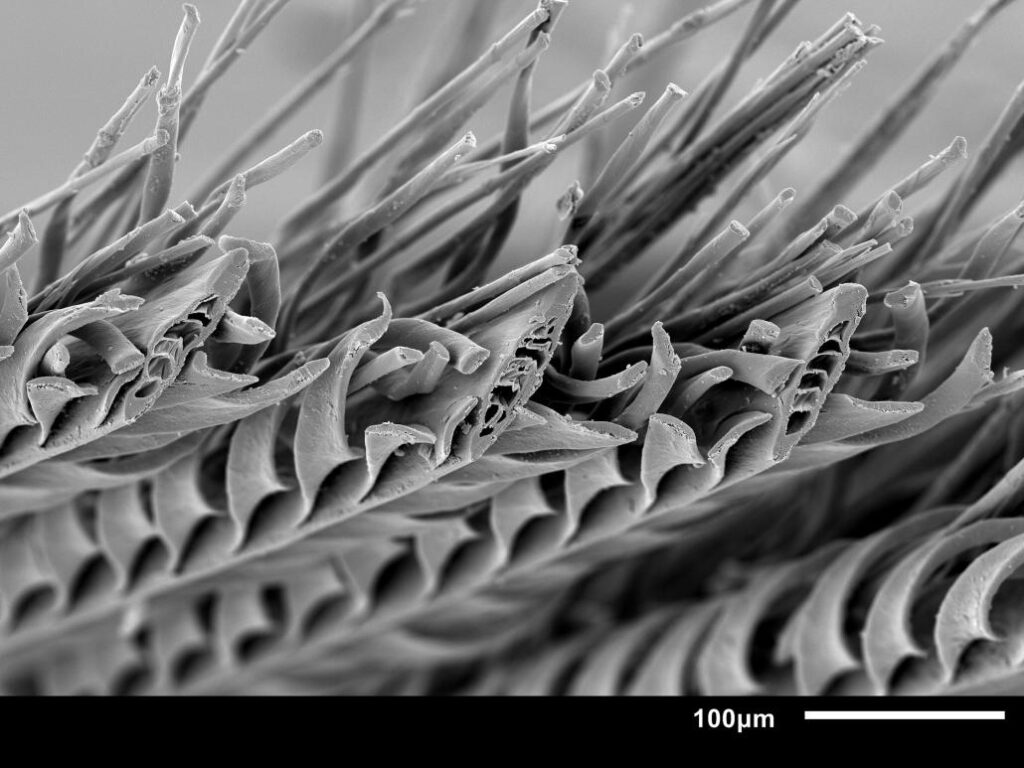

Above photo: An extreme closeup of a male sandgrouse feather, which has an uncanny ability to hold water while it flies and could inspire the next generation of absorbent materials

Story by Jill Rosen and was published on the Hub.

An extreme closeup of feathers from a bird with an uncanny ability to hold water while it flies could inspire the next generation of absorbent materials.

With high resolution microscopes and 3D technology, researchers at Johns Hopkins University and Massachusetts Institute of Technology captured an unprecedented view of feathers from the desert-dwelling sandgrouse, showcasing the singular architecture of their feathers and revealing for the first time how they can hold so much water.

“It’s super fascinating to see how nature managed to create structures so perfectly efficient to take in and hold water,” said co-author Jochen Mueller, an assistant professor in Johns Hopkins’ Department of Civil and Systems Engineering, who specializes in smart materials and design. “From an engineering perspective, we think the findings could lead to new bio-inspired creations.”

The work was published Tuesday in the Journal of The Royal Society Interface.

Sandgrouse found in African deserts typically nest about 20 miles from watering holes to stay safe from predators. To get water home to thirsty chicks, the adult males perform one of nature’s best examples of carry out, gathering water and flying home with it, a feat made even more extraordinary considering the sandgrouse is holding about 15% of his body weight in water, and keeping most of it safe during a roughly 40 mph flight home that takes about a half hour.

The male sandgrouse are the only birds known to hold water like this—their specially adapted belly feathers are the key.

Other researchers first documented these extraordinary belly feathers more than 50 years ago. But only here with modern technology the team can finally demonstrate how the feathers work.

Mueller and MIT engineer Lorna J. Gibson zeroed in on the microstructure of the belly feathers using scanning electron microscopy, microcomputed tomography, light microscopy and 3D videography, looking closely at the shafts, each just a fraction of the width of a human hair, and the even tinier individual barbules.

The team greatly magnified the feathers, observing them both dry and wet. Then, in a move as delicate as it was crucial, while magnified the dry feathers were dunked in water, pulled out, then re-submerged, just like a sandgrouse at a watering hole.

“When you do that type of work, you can’t even breathe or else you blow it away,” Mueller said.

Mueller described the individual feather structure as “magnificent,” with components optimized in several ways to hold and retain water, including the way they bend, how the barbules form protective tentlike clusters when wet, and how tubular structures within each barbule capture water.

Individual feathers held the water through a forest of barbules near the shaft, working together with the curled barbules near the tip acting almost like caps.

“That’s what excited us, to see that level of detail,” Mueller said. “This is what we need to understand in order to use those principles to create new materials.”

The team also computationally modeled the water intake of the feathers.

Mueller and Gibson expect their findings will underpin future engineering designs requiring controlled absorption, secure retention, and easy release of liquids.

Possible applications include the design of netting for collecting and retaining water from fog and dew in desert regions; and a water bottle designed to prevent annoying swinging and sloshing.

For the water bottle or sports backpack, he’s thinking about a design that safely holds a lot of liquid, but includes an inner feather-like system that keeps the water from swinging around while someone moves with it. He thinks a hydration pack or water bladder that could do this would be particularly appreciated by runners.

He also imagines next-level medical swabs that are easier to use, “where you can efficiently soak up liquid, but it’s much easier to release it,” he says, adding that the release feature was an issue for collecting COVID-19 nasal test samples during the pandemic.

Next the team plans to print similar structures in 3D and pursue commercial applications.

Latest Posts

-

Cellular building blocks may enable new understanding of the body’s “machinery”

December 19, 2025

Cellular building blocks may enable new understanding of the body’s “machinery”

December 19, 2025

-

Biomedical Engineer Jamie Spangler Receives President’s Frontier Award

December 15, 2025

Biomedical Engineer Jamie Spangler Receives President’s Frontier Award

December 15, 2025

-

Johns Hopkins Postdoc Named in Forbes `30 Under 30′ List

December 8, 2025

Johns Hopkins Postdoc Named in Forbes `30 Under 30′ List

December 8, 2025