Ammonia May Unlock Secrets to Cleaner, Greener Energy

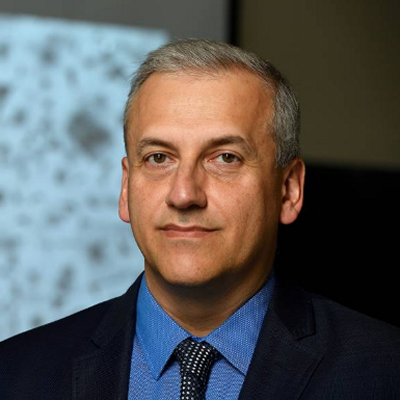

Research effort led by Bloomberg Distinguished Professor Michael Tsapatsis aims to test ammonia’s potential as a liquid storage medium

Does the secret to cleaner energy lie in a common household cleaner?

With its unmistakable smell and astringent nature, ammonia is used to combat household grime, from greasy stovetops to soap-scummed bathroom tiles. Now, a Johns Hopkins chemical and materials engineer thinks it may also hold the key to cleaner, more sustainable energy.

Michael Tsapatsis, the Bloomberg Distinguished Professor of nanomaterials with appointments in the Department of Chemical and Biomolecular Engineering and the Johns Hopkins University Applied Physics Laboratory, is leading a team that is investigating how to efficiently manufacture ammonia and its potential uses in creating clean fuel technologies.

The three-year, $4.2 million project is funded by the U.S. Department of Energy and is part of its $540 million overall initiative aimed at supporting research and developing new technology to reduce carbon emissions and advance clean energy. Ammonia has potential as a liquid storage medium as it does not produce carbon dioxide when burned.

“How to make chemicals pure from the beginning instead of purifying them afterwards is one important aspect of sustainability,” said Tsapatsis, whose group has been developing very thin membranes that separate molecules by size and affinity, and recently discovered a membrane that can separate ammonia from hydrogen and nitrogen.

“So the idea is now you can have a reactor, like a tube, and you can pack this tube with a catalyst that accelerates the rate of the ammonia production from a nitrogen/hydrogen mixture, but predominantly the ammonia gets released through the walls of the reactor. In this way you can produce a clean product, and don’t have to separate the ammonia afterwards.”

Exploring ways of manufacturing ammonia using wind energy or biogas to electrically derive its constituent molecules by obtaining hydrogen from water and nitrogen from air is a key component of the project. Focused on what’s known as transformative manufacturing, the project addresses the chemical production of ammonia in highly integrated and co-designed reaction-separation systems.

“To help discover new ways to combine reaction and separation, we are pushing computational modeling and machine learning in new directions,” said Brandon Bukowski, assistant professor in the Department of Chemical and Biomolecular Engineering and a co-investigator on the project. “We want to predict how a membrane reactor will perform before it’s made so that we can accelerate the development process and find an optimal solution. We have a great team of experimental and computational researchers both here and at the partner institutions to develop a synergistic design loop.”

In addition to Bukowski, Johns Hopkins co-investigators include Chao Wang, associate professor in the Department of Chemical and Biomolecular Engineering, as well as David Elbert, associate research scientist in the Krieger School of Arts and Sciences’ Department of Earth and Planetary Sciences. Other co-investigators are Rebecca K. Lindsey, assistant professor at the University of Michigan; Prodromos Daoutidis and J. Ilja Siepmann, professors at the University of Minnesota; and Arturo J. Hernández-Maldonado, professor at the University of Puerto Rico, Mayagüez. ExxonMobil and University of Erlangen-Nuremberg are participating partners.

Story by Jonathan Deutschman and was published on the Hub on October 14, 2022.

Latest Posts

-

Cellular building blocks may enable new understanding of the body’s “machinery”

December 19, 2025

Cellular building blocks may enable new understanding of the body’s “machinery”

December 19, 2025

-

Biomedical Engineer Jamie Spangler Receives President’s Frontier Award

December 15, 2025

Biomedical Engineer Jamie Spangler Receives President’s Frontier Award

December 15, 2025

-

Johns Hopkins Postdoc Named in Forbes `30 Under 30′ List

December 8, 2025

Johns Hopkins Postdoc Named in Forbes `30 Under 30′ List

December 8, 2025